Zu diesen Produkten zählen nicht nur einzelne Bauteile und Baugruppen sondern auch Systemkomponenten unterschiedlichster Komplexität, z.B. für Motor, Chassis, Getriebe und Fahrwerk (Achse, Lenkung, Bremse).

Schlote produces semi-finished products in large series, mainly using machining methods with the latest technologies in the highest quality. In CNC processing centres and automated production lines, the company processes a variety of metals such as various castings, metal alloys and forged materials.

Housings, main bearings, mountings, holders for turbochargers, injection pumps, crankshaft bearing covers, parts for the electric drive train and outer rings for wheel bearings are among the products that are machined and hardened. Production is further optimised through ongoing investments in new automation technologies, making jobs cleaner and more attractive.

Metal processing and construction of motor components

Schlote also produces fully assembled motor components. Among other things, we have specialised in the production of bed plates, crankshaft bearing covers, turbine housings, exhaust manifolds, power-train mounts, sealing flanges and pump casings.

Examples of the motor system components processed by us include:

- Exhaust manifolds

- Petrol pumps

- Base plates

- Sealing flanges

- Holders and mounting brackets

- Crankshaft bearing covers

- Bearing pins

- Bearing housing

- Bed plates

- Oil pump casings

- Oil pump covers

- Intake manifolds

- Timing cases

- Turbines

- Turbo exhaust manifolds

- Cylinder heads

- Other motor components

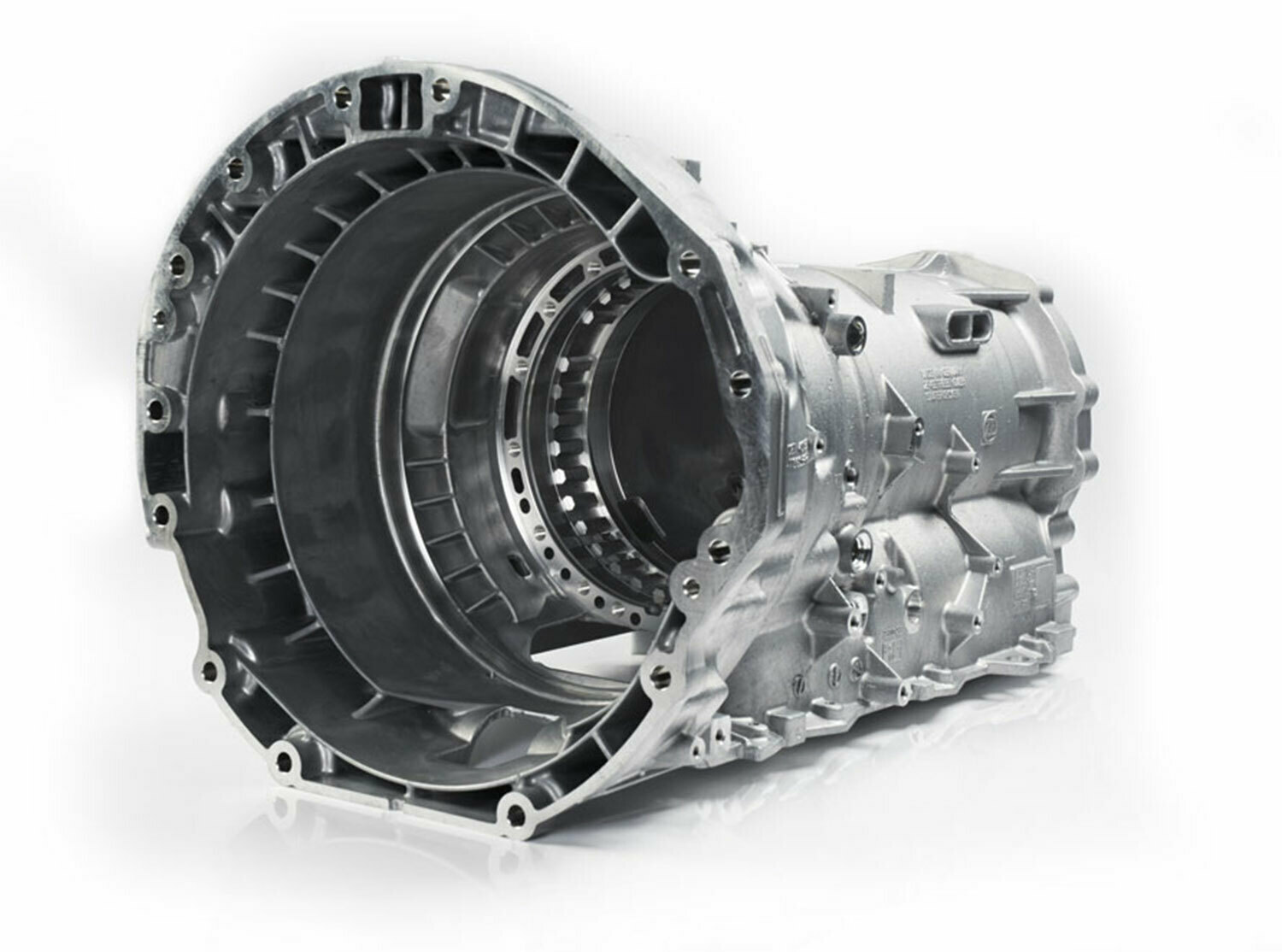

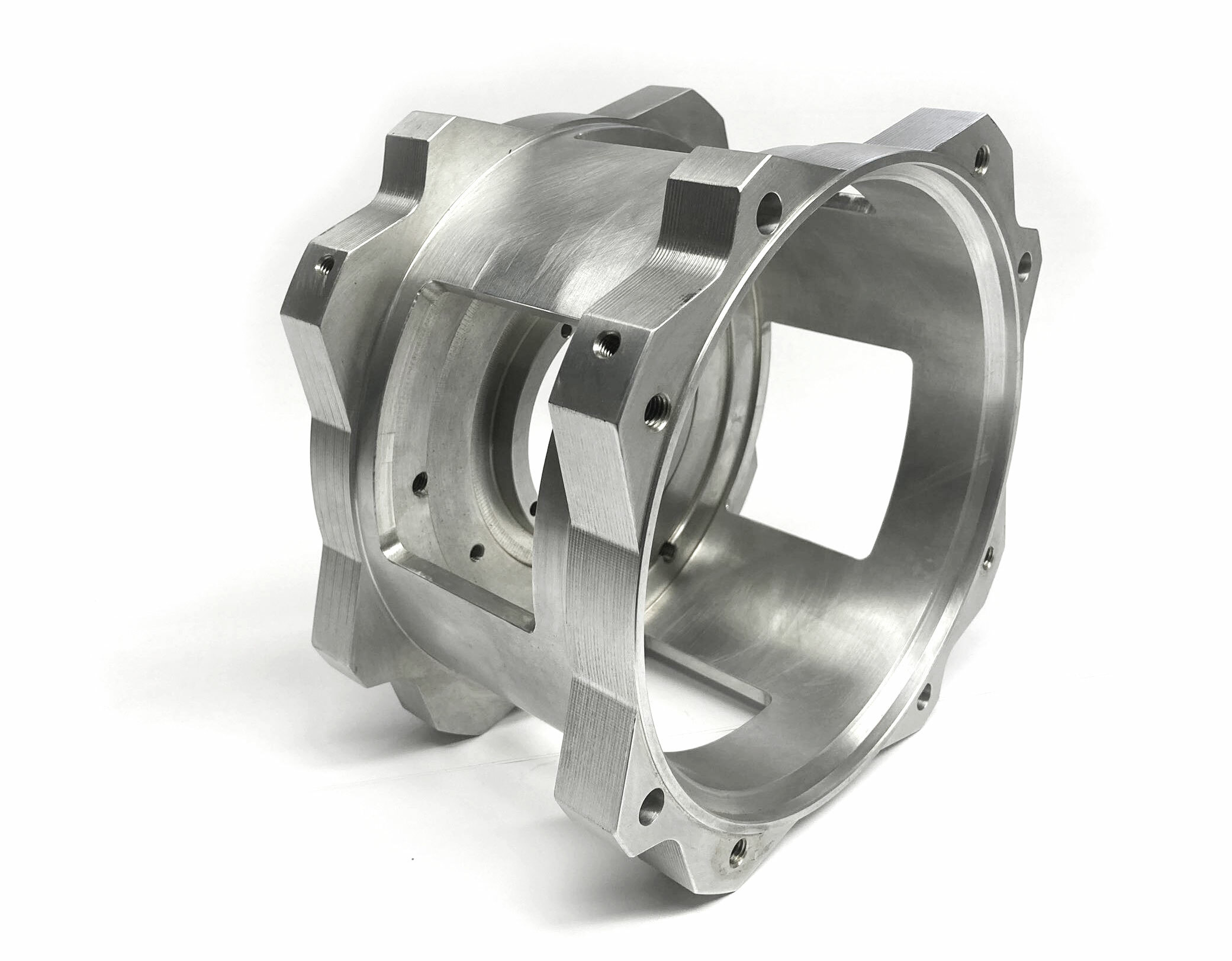

Metal processing and construction of transmission components

We process transmission components for nearly all fields of application. Among other things, Schlote specialises in the machining of transmission housings, converter housings and diesel injection pumps. We strive to be a competitive supplier of high-quality components and assemblies, involved in the customer’s development process in a timely manner and identifying all possibilities for cost-effective processing from the outset. Just-in-time delivery of small, medium and large series to our customers with high quality is one of our goals. We tirelessly dedicate ourselves to quality and reliability. Our profession is the production of components and systems for the automobile, vehicle and supplier industry with maximum process reliability. Our passion is to meet the needs and requirements of our customers, supplying products of high quality at fair prices.

We have specialised in the production of complex, highly precise component groups for manual and automatic transmission applications. Complete assemblies are supplied as well. All components are subject to strict requirements with regard to accuracy, residual soiling and leak tightness. The transmission system components processed by us include:

- Cover plates

- Differential flanges

- Transmission mounting parts

- Transmission covers

- Transmission housings

- Rear axle housings

- Clutch housings

- Bearing supports

- Gear shift housings

- Other transmission components

Metal processing of structural and chassis components

We produce fully assembled components and assemblies in the bearings and kinematics field for the front and rear axles. These include inner and outer rings for wheel bearings as well as rocker arms, main bearings and pivot bearings. Examples of the chassis system components processed by us include:

- Main bearings

- Mounting brackets

- Crankcases

- Steering boxes

- Pivot bearings

- Rocker arms

- Other chassis components

Component manufacturing for machinery and equipment

We produce finished parts, assembled components and assemblies of the highest quality for mechanical engineering and plant construction with maximum vertical integration.

Our expertise is not limited to the production of parts and components according to drawings. We advise our customers regarding production-friendly design and the optimisation of component diversity – with great flexibility regarding quantity adjustments and readiness to deliver.

Your full-range service provider for component manufacturing

Our component manufacturing includes:

- Drive system components

- Parts, components and assemblies for machine tools

- Mechanical components for agricultural machinery, construction vehicles and industrial trucks

- Components, assemblies and parts for railway engineering

- Development and production of series systems in toolmaking, mechanical engineering and plant construction

Your goal is our goal

We consistently strive to be a competitive supplier of high-quality components and assemblies, involved in the customer’s development process in a timely manner and identifying all possibilities for cost-effective processing from the outset. Just-in-time delivery of small, medium and large series to our customers with high quality is one of our goals. We tirelessly dedicate ourselves to quality and reliability. Our profession is the production of components and systems for industry with maximum process reliability. Our passion is to meet the needs and requirements of our customers, supplying products of high quality at fair prices – with certified quality of our mechanical engineering components and all other products manufactured or processed by us.

Best practices: Schlote component manufacturing

Schlote built one of the most modern and innovative production facilities for installation-ready housing components in 2006. These housings are produced in automated production lines. Our processes and procedures are subject to continuous improvement. High-performance tools and a standard ERP system support advance quality planning and the analysis of all quality data. We operate an integrated management system across all locations, putting customer satisfaction first. We are increasingly relying on automated workflows, including integrated assembly processes.

A high degree of automation guarantees optimal quality standards with corresponding process capabilities for our customers.

Schlote Holding GmbH

Carl-Zeiss-Straße 1

31177 Harsum

+ 49 (0) 5127 / 971- 0

andreas.hornkamp@schlote.com

Industrial Technology Solutions

Are you interested in industrial solutions and services outside of medium and large series production?